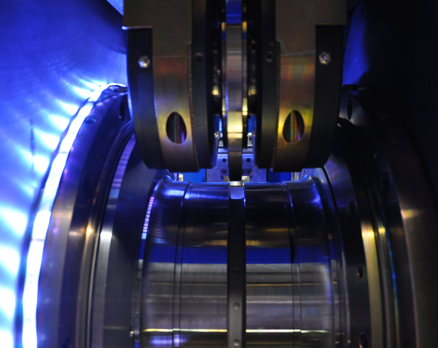

Continually investing in new technology and innovations for precision control and operational efficiencies.

Continually investing in new technology and innovations such as our unique patented ‘Dynamic Shoe Positioning System’ (DSPx2) for precision control and operational efficiencies.

Continually investing in new technology and innovations such as our unique patented ‘Dynamic Shoe Positioning System’ (DSPx2) for precision control and operational efficiencies.